Water-cooled Fluid Cooling type

Meets variety of fluids by selecting liquid contact part from aluminum and titanium

Features

| Environment of use | Cooling method | Heat dissipation | Type of cooling |

| Indoor | Thermoelectric | Water cooling | Fluid cooling |

Certificates/Approvals

| EU RoHS | China RoHS | CE | UL | CSA | PSE |

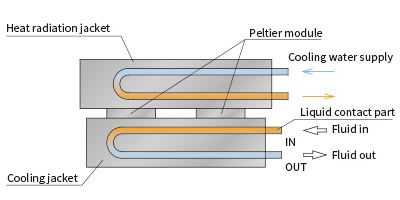

Cooling cycle

Fluid flown in from the inlet port of the cooling block is cooled by passing through the cooling block and the liquid contact part, which have been cooled by thermoelectric module, and then flows out from the outlet port. The absorbed heat and the generated heat are water-cooled to be dissipated through heat conductive materials like aluminum from the opposite side of the thermoelectric module. (*1)

(*1) The heat absorbed through the heat dissipation fin is exhausted from the fan on heat dissipation side.

(*1) The heat absorbed through the heat dissipation fin is exhausted from the fan on heat dissipation side.

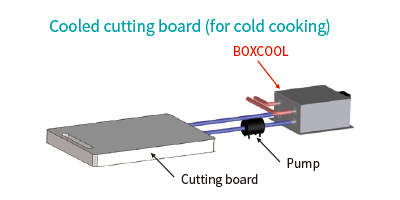

Example of use

Model/Specifications

| Model | OCE-L80LA -D24 |

OCE-L80LT -D24 |

OCE-L160LA -D24 |

OCE-L160LT -D24 |

|

| Cooling method | Water-cooled fluid cooling | ||||

| Cooling capacity *1 | 140W | 125W | 300W | 240W | |

| Heating capacity *2 | 240W | 480W | |||

| Rated voltage | 24VDC ±5% | ||||

| Current consumption *3 | 10.3A or less | 20.5A or less | |||

| Starting current *4 | 11.0A | 21.5A | |||

| Working temperature |

0 to +50℃ | ||||

| Working humidity |

Max. 80%RH, free from condensation | ||||

| Liquid temperature |

Cooling side *5 | Max. +50℃, ice-free | |||

| Heat dissipation side | 0 to +50℃ | ||||

| Min. flow rate |

Cooling side | - | |||

| Heat dissipation side *6 | 2L/min | 3L/min | |||

| Max. allowable temeprature for cooling block |

+80℃ | ||||

| Max. allowable temeprature for water-cooled block |

+80℃ | ||||

| Overheat protection on heat dissipation side |

Water-cooled block, thermal fuse integrated | ||||

| Vibration resistance |

Vibration frequency 10-55Hz Total amplitude 0.7mm Cycle 5min X, Y and Z axis 25min each |

||||

| Conformity to standards | Environment | RoHS | |||

| Circultion fluid |

Cooling side | Purified water, tap water, etc. | |||

| Heat dissipation side | |||||

| Liquid contact part |

Cooling side | Aluminum (SUS304 partially) |

Titanium | Aluminum (SUS304 partially) |

Titanium |

| Heat dissipation side | Aluminum(SUS304 partially) | ||||

| Pressure resitance in piping | Cooling side | 0.5MPa | |||

| Heat dissipation side | |||||

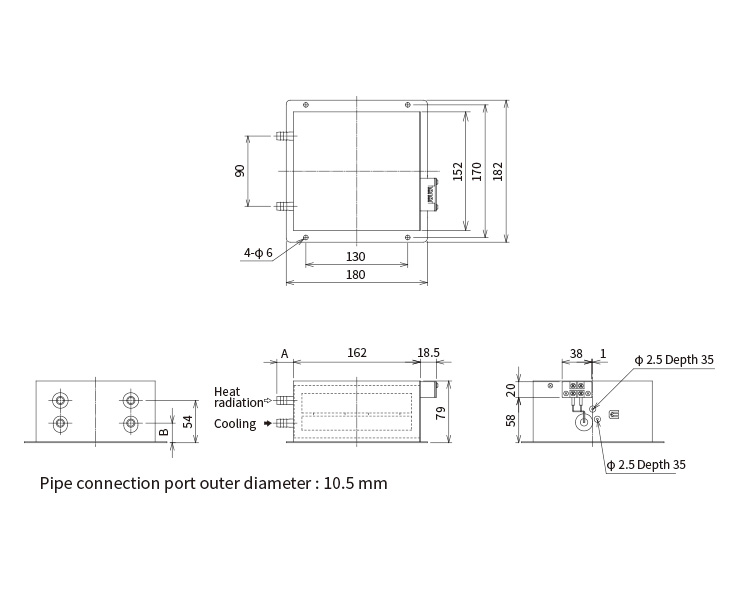

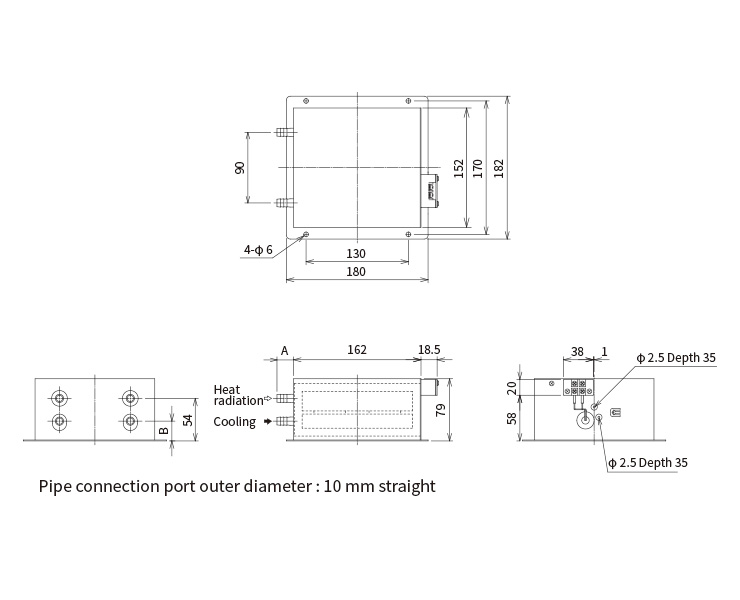

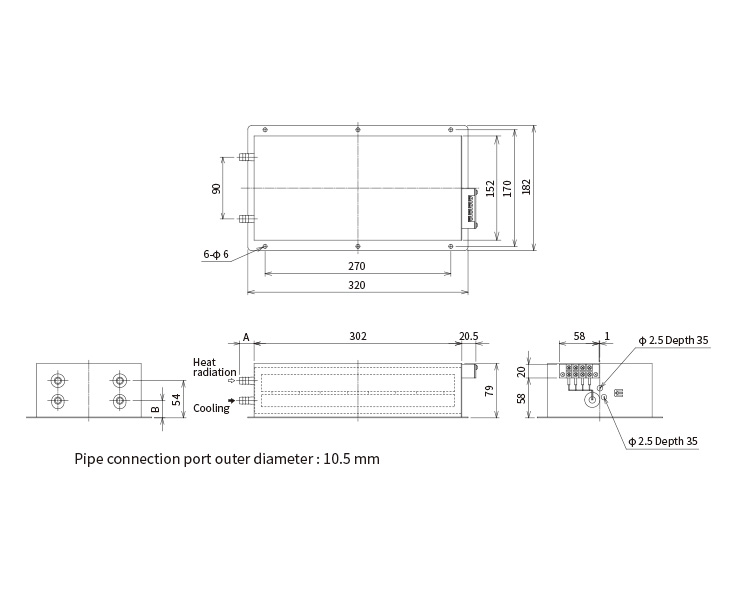

| Outer diameter of pipe connection port | Cooling side | Ø10.5 | Ø10 | Ø10.5 | Ø10 |

| Heat dissipation side | Ø10.5 | ||||

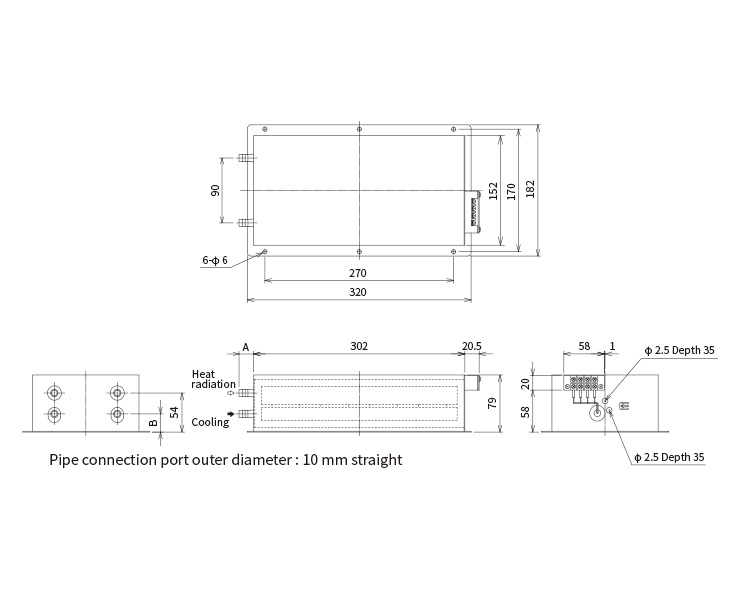

| Dimensions (mm)*7 | W180×H79×D182 | W320×H79×D182 | |||

| Weight | 3.2kg | 5.2kg | |||

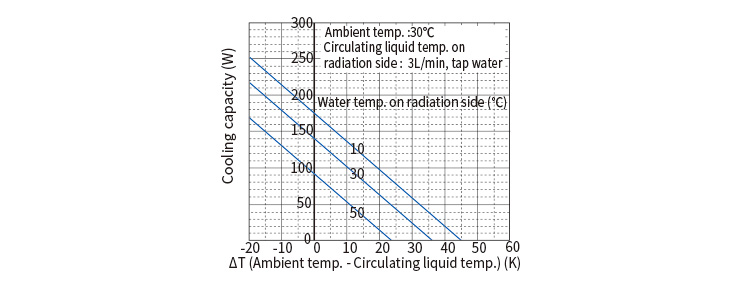

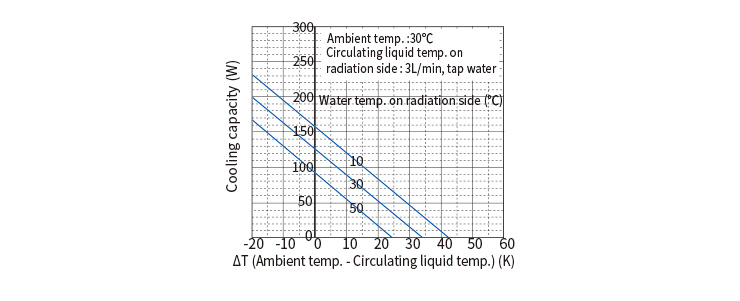

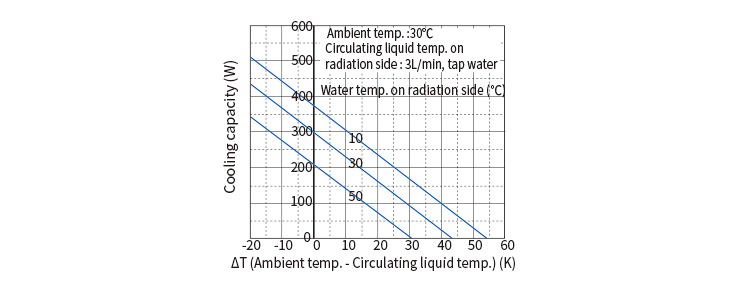

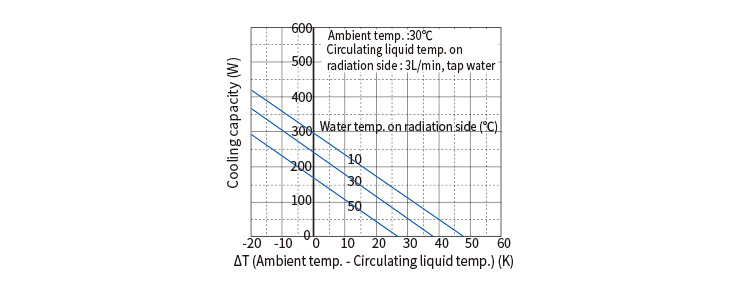

*1 Nominal value when ambient temp. and water temp. on heat dissipation side are 30℃ and flow rate is 3 L/min, by applying our capacity measurement method by product type.

*2 Nominal value when ambient temp., water temp. on heat dissipation side and circulation liquid temp. are 30℃.

*3 Rated value when ambient temp. and water temp. on heat dissipation side are 30℃ with cooling operation . (The value varies depending on temperature. See the table below. )

*4 Starting current when ambient temp. and water temp. on heat dissipation side are 30℃. (The value varies depending on temperature. See the table below. )

*5 Pay attention to prevent circulation liquid from freezing.

*6 Performance declines by decrease in flow rate.

*7 Terminal board and projection are excluded.

*2 Nominal value when ambient temp., water temp. on heat dissipation side and circulation liquid temp. are 30℃.

*3 Rated value when ambient temp. and water temp. on heat dissipation side are 30℃ with cooling operation . (The value varies depending on temperature. See the table below. )

*4 Starting current when ambient temp. and water temp. on heat dissipation side are 30℃. (The value varies depending on temperature. See the table below. )

*5 Pay attention to prevent circulation liquid from freezing.

*6 Performance declines by decrease in flow rate.

*7 Terminal board and projection are excluded.

Correlation between temperature and current value

| Ambient temperature | 0℃ | 30℃ | 50℃ | |

| OCE-L80LA/LT-D24 | Rated current consumption (A) | 11.8 | 10.3 | 9.3 |

| Starting current (A) | 12.4 | 11.0 | 10.1 | |

| OCE-L160LA/LT-D24 | Rated current consumption (A) | 23.1 | 20.5 | 18.3 |

| Starting current (A) | 24.2 | 21.5 | 19.3 |

Contents of page

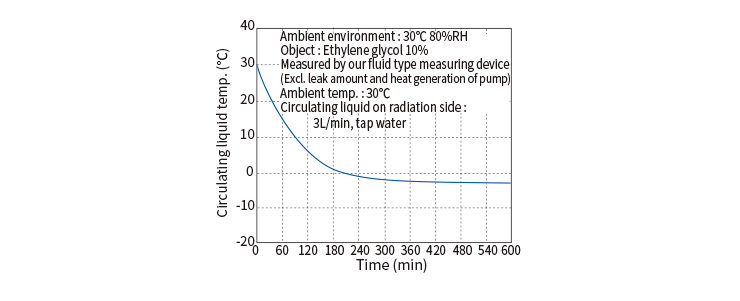

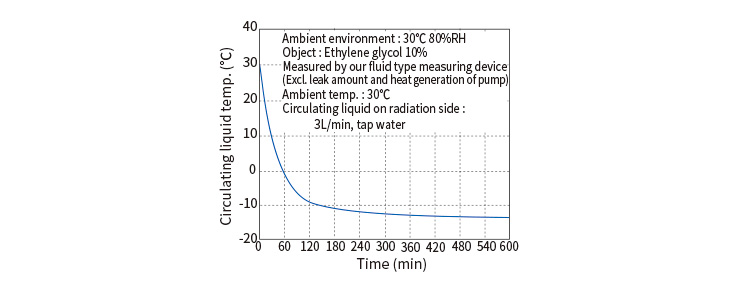

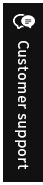

OCE-L80LA/LT-D24

Cooling capacity

L80LA:140W L80LT:125W

A complete set of supply

BOXCOOL : 1 unit Instruction manual : 1 copy

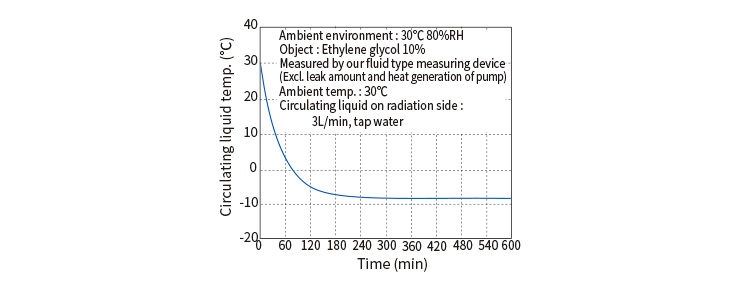

OCE-L160LA/LT-D24

Cooling capacity

L160LA:300W L160LT:240W

A complete set of supply

BOXCOOL : 1 unit Instruction manual : 1 copy

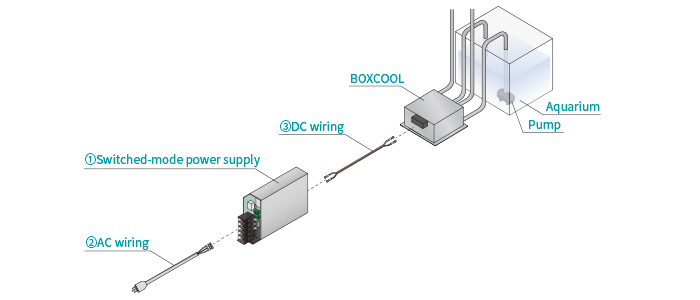

System combination

By combination of BOXCOOL and components, various systems having different operation control from continuous operation to precise inversion control can be built.

①Continuous cooling

Combines BOXCOOL with a power supply for continuous running

| Component name | Model | ||

| OCE-L80LA-D24 OCE-L80LT-D24 |

OCE-L160LA-D24 OCE-L160LT-D24 |

||

| ① | Switched-mode power supply | PBA300F-24 | PBA600F-24 |

| ② | AC wiring ※1 | WH-A-M4-2 | |

| ③ | DC wiring | WH-P-M5-2 | WH-P-M5-2 (2 pcs) |

*1 For 100VAC power supply

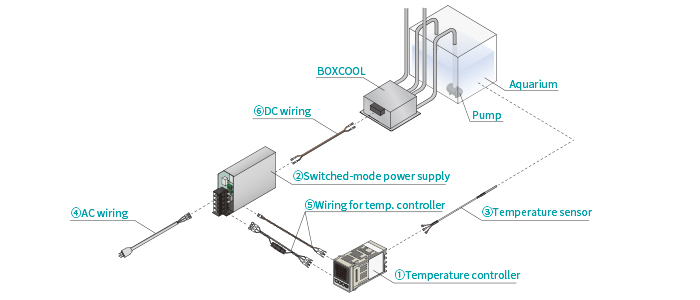

②Simple thermal control system

ON/OFF control is done by a temperature controller using a contact in the power supply.

| Component name | Model | ||

| OCE-L80LA-D24 OCE-L80LT-D24 |

OCE-L160LA-D24 OCE-L160LT-D24 |

||

| ① | Temperature controller | OCE-TC91-8Y1-1C | |

| ② | Switched-mode power supply | PBA300F-24 | PBA600F-24 |

| ③ | Temperature sensor | OCE-TCPT** | |

| ④ | AC wiring ※1 | WH-A-M4-2 | |

| ⑤ | Wiring to temperature controller | WH-C2 | |

| ⑥ | DC wiring | WH-P-M5-2 | WH-P-M5-2 (2 pcs) |

*1 For 100VAC power supply

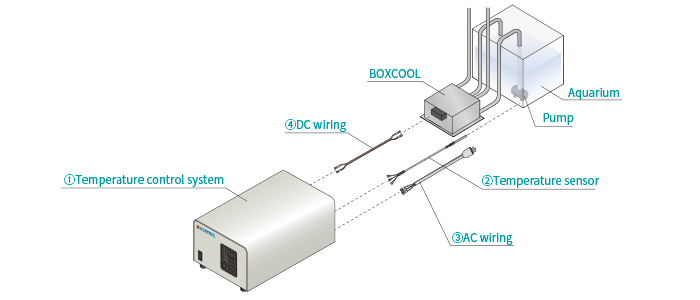

③Precise inversion control system

Highly precise temperature control is achieved by linear voltage controlled switching of cooling and heating using our Temperature Control system designed for BOXCOOL.

| Component name | Model | ||

| OCE-L80LA-D24 OCE-L80LT-D24 |

OCE-L160LA-D24 OCE-L160LT-D24 |

||

| ① | Temperature control system | OCE-TCR24300WL | OCE-TCR24600WL |

| ② | Temperature sensor | OCE-TCPT** | |

| ③ | AC wiring *1 | WH-A-M4-2 | |

| ④ | DC wiring | WH-P-M4-2 | WH-P-M4-2 (2 pcs) |

*1 For 100VAC power supply

Cautions

・Do not use this product in a place where flammable or corrosive gasses, oil fume or any matters that can destroy insulation generate or permeate.

・The site of use should be free from vibration and impact.

・Electrical works required for installation of this product should be done only by professionals or qualified personnel.

・Withstand pressure of the fluid block is 0.5MPa.

・Indoor use only.

・Make sure that the packaging is not damaged on delivery. Any packaging damage can lead to breakdown of the product. Please contact us immediately if any damage is found.

・The site of use should be free from vibration and impact.

・Electrical works required for installation of this product should be done only by professionals or qualified personnel.

・Withstand pressure of the fluid block is 0.5MPa.

・Indoor use only.

・Make sure that the packaging is not damaged on delivery. Any packaging damage can lead to breakdown of the product. Please contact us immediately if any damage is found.