JB-W series CAPCON integrated, Easy connection

Remarkably improves your working efficiency.

Features

| Protection category | Color | Rated voltage | Rated current | Oilproof | Weatherproof | Number of terminals |

| IP67 | Black/Light gray | 600V | 20A | ✓ | ✓ | 4P |

Certificates/Approvals

| EU RoHS2 | China RoHS | CE | UL | CSA | PSE |

Model/Specification

Oilproof type Rubber busing:Black

| Model | Rated voltage | Working temperature | Nominal section area of cable | Number of terminals | Weight (*1) |

Q'ty per package | |

| Black | Light gray | ||||||

| JB-W44 | JB-W44C1 | AC/DC 600V 20A |

-25 to +80℃ | 2.0mm2 or less |

4P | 95g | 1 pc. |

Weatherproof type Rubber bushing:Blue

| Model | Rated voltage | Working temperature | Nominal section area of cable | Number of terminals | Weight (*1) |

Q'ty per package | |

| Black | Light gray | ||||||

| JB-W44E | - | AC/DC 600V 20A |

-25 to +80℃ | 2.0mm2 or less |

4P | 95g | 1 pc. |

*1 Weight values are for Black color.

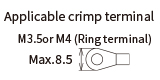

Applicable cable diameter/Accessories

| Model of rubber bushing | Applicable cable diameter(mm) | Q'ty |

| G13-13/13E | Ø11 to13 | 1 |

| G13-602/602E | Ø5 to 6(2 holes) | 1 |

| Model of rubber bushing | Applicable cable diameter(mm) | Q'ty |

| G13-09/09E | Rubber bushing A+B Ø3 to 6 Rubber bushing A only Ø6 to 9 |

1 |

| G13-11/11E | Ø8.5 to 11.5 | 1 |

| G13-404/404E | Ø3 to 4(4 holes) | 1 |

| Model of plugging bar | Specification | Q'ty |

| BB-40S | For G13-404/404E | 2 |

Instructions

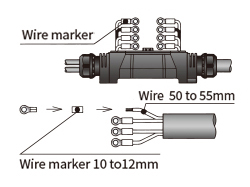

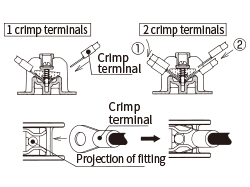

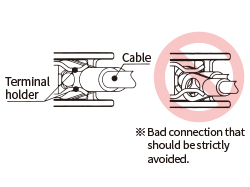

1.Insert cables from the openings on each end (through the CAPCON) and crimp the fork terminals.

2.Insert a ring terminal into the terminal strip until it locks in to place.(*) Pull back on the terminal to ensure it has caught in the initial locking position.

*Note:Secure Lock Position

Insert the ring terminal until it clicks.The opposing terminal will make no sound when inserted.

【Cautions】Confirm the terminals are in locked position.

<For the first terminal>Pull the cable to make sure that the ring terminal is held in position.

<For the second terminal>Verify that the neck of the ring terminal is evenly held down by the terminal strip.

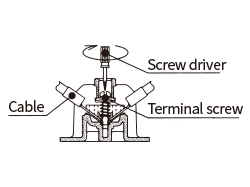

3.Tighten the provided terminal screws using a screw driver.

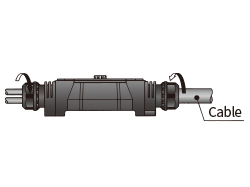

4.Tighten the dome nut to fasten the cable.

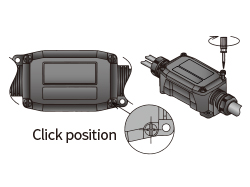

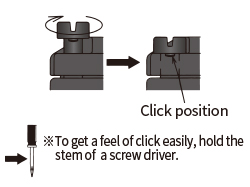

5.Tighten the lid screws until they click, signifying the optimum tension.

【Cautions】Avoid tightening over the click position.Failure to this may damage the screws and lead to degrade the water-tightness.

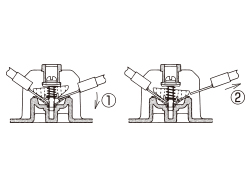

【Diassembly】Loosen the terminal screw and remove the cable in two steps. ①1.Push the ring terminal down.②2.Pull the ring terminal out while holding the terminal down.

- Use only one cable for one hole.

- Tightening torque and strength differ depending on the material of cable coating and its hardness.

- Tensile strength and waterproof performance drops when outer cable diameter changes due to aging.

- Products performance are not guaranteed for cables other than the applicable size or round cables.

Option

Cautions

*Do not use this product in oil or water.

*To prevent deterioration, avoid using or storing this product under the following atmospheres.

- Outside the range of working temperature

- Water vapor contained or high temperature/humidity air

- Acidic, alkaline or organic solvent-containing air (See Technical Data "Chemical resistance")

- Oilproof type (Rubber color : black)

Do not expose to direct and continuous sunlight.

Suitable for oily environments.

*For non-oily places, use Weatherproof type. - Weatherproof Type (Rubber color : blue)

Avoid using in oily environments.

For non-oily indoor places, Weatherproof type is recommended.

Wiring precautions

*Avoid direct sunshine in outdoor use.

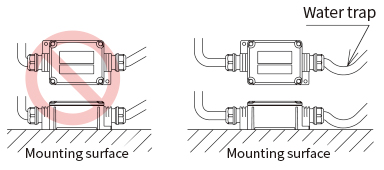

*To prevent entry of water dropping along the cable, pay attention to the following matters.

- Do not place the JOIBOX so as the cable entry is in an upward direction.

- When the cable is drawn from higher position, provide a water trap or a horizontal portion.