IP ratings

What is IP rating?

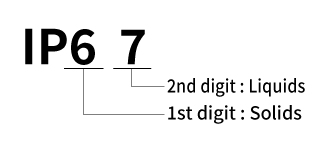

IP ratings indicate the degree of protection against intrusion of solids and liquids. It consists of the letters IP followed by two digits.

First digit - Solids

The first digit of the IP rating indicates the degree of protection or limitation against ingress of a part of human body or tools held by a person to protect people against access to hazardous parts and the ingress of solid foreign objects into the enclosure.

| 1st digit | Protected against | Test condition | Protected against | Test condition |

| 0 | Not protected | - | Not protected | - |

| 1 | Any large surface of the body such as the back of a hand | An access probe, sphere of 50mm in diameter, shall have adequate clearance from hazardous parts. | Solid foreign objects of 50 mm or larger in diamter | An object probe, sphere of 50 mm in diameter, shall not fully penetrate. |

| 2 | Fingers or similar objects | The tip of a jointed test finger of 12mm in diameter and 80 mm long shall have adequate clearance from hazardous parts. | Solid foreign objects of 12.5 mm or larger in diamter | An object probe, sphere of 12.5 mm in diameter, shall not fully penetrate. |

| 3 | Tools, thick wires, etc. | An access probe, sphere of 2.5mm in diameter, shall not penetrate. | Solid foreign objects of 2.5 mm or larger in diamter | An object probe, sphere of 12.5 mm in diameter, shall not penetrate at all. |

| 4 | Wires | An access probe, sphere of 1.0mm in diameter, shall not penetrate. | Solid foreign objects of 1.0 mm or larger in diamter | An object probe, sphere of 1.0 mm in diameter, shall not penetrate at all. |

| 5 | Wires | An access probe, sphere of 1.0mm in diameter, shall not penetrate. | Dust-resistant | Ingress of dust is not totally prevented, but dust shall not penetrate in an amount to interfere with satisfactory operation of the apparatus or to impair safety. |

| 6 | Wires | An access probe, sphere of 1.0mm in diameter, shall not penetrate. | Dust-tight | No ingress of dust |

Second digit - Liquids

The second digit of the IP rating indicates the degree of protection against harmful ingress of water.

| 2nd digit (JIS Protection Class) |

Protected against | Test condition |

| 0(0) | Not protected | - |

| 1(1) | Vertically falling water drops | In installed state, expose to water equivalent to 1mm rainfall per minute falling from a height of 200mm above for 10 minutes |

| 2(2) | Water drops falling in a range of 15 deg. angle from vertical | In installed state, expose to water equivalent to 3mm rainfall per minute for four direction (front, back, left and right) tilted at 15 degrees to the vertical plane from a height of 200mm or higher for 2.5 minutes each (10 minutes in total) |

| 3(3) | Water falling as spray at an angle up to 60 deg. from vertical | In installed state, spray water on the apparatus from a height of 300 to 500mm above using a spray nozzle covering the range from vertical to 60 degrees tilt off vertical on both sides. Water volume: 10 ±0.5 litres per minute, water pressure: 50 to 150 kPa, test duration: 1 minute per 1sqm of the outer surface of the apparatus, at least 5 minutes in total |

| 4(4) | Splashing water from any angle | In installed state, spray water on the apparatus from a height of 300 to 500mm above using a spray nozzle covering the range from vertical to 180 degrees tilt off vertical on both sides. Water volume: 10 ±0.5 litres per minute, water pressure: 50 to 150 kPa, test duration: 1 minute per 1sqm of the outer surface of the apparatus, at least 5 minutes in total |

| 5(5) | Water projected in jets from any direction | In installed state, water is projected in jets against the apparatus from any direction using the designated spray nozzle of 6.3mm inner diameter. Distance between nozzle and apparatus: 2.5 to 3m, water volume: 12.5 litres ±5% per minute, water flow diameter: about 40mm at a distance of 2.5m from the nozzle end, test duration: 1 minute per 1sqm of the outer surface of the apparatus, at least 3 minutes in total |

| 6(6) | Water projected in jets from any direction | In installed state, water is projected in jets against the apparatus from any direction using a designated spray nozzle of 12.5mm inner diameter. Distance between nozzle and apparatus: 2.5 to 3m, water volume: 100 litres ±5% per minute, water flow diameter: about 120mm at a distance of 2.5m from the nozzle end, test duration: 1 minute per 1sqm of the outer surface of the apparatus, at least 3 minutes in total |

| 7(7) | No ingress of water when the enclosure is immersed in water under defined conditions | Leave the apparatus in water for 30 minutes in a position so as the highest point is positioned 150 mm or more beclow the water surface and the lowest point is positioned 1000 mm of more below the surface. |

| 8(8) | Suitable for use being immersed in water under a specified pressure | Based on the agreement between the manufacturer and the user |

【Reference materials】

Japanese Industrial Standard JIS C 0920-1993 "Tests to prove protection against ingress of water and degrees of protection against ingress of solid objects for electrical equipment"

The Japan Electrical Manufacturers' Association Standard: JEM 1267-1986 ”Types of protection classes for switchboards and control panels"

German Institute for Standardization DIN 40050

International Electrotechnical Commission IEC 144, IEC 529

Japanese Industrial Standard JIS C 0920-1993 "Tests to prove protection against ingress of water and degrees of protection against ingress of solid objects for electrical equipment"

The Japan Electrical Manufacturers' Association Standard: JEM 1267-1986 ”Types of protection classes for switchboards and control panels"

German Institute for Standardization DIN 40050

International Electrotechnical Commission IEC 144, IEC 529